It is widely recognised there are differences between industries in the way that technology is adopted, adapted and applied, but differences within industries generally get less attention. Technology adoption within industries depends on the different individual characteristics of firms, which affects the rate and extent of adoption of new technologies. and the competitive dynamics, or how the adoption of new technology by one firm influences the adoption of technology by other firms. This post discusses technology adoption and hidden innovation in construction.

Contemporary construction products and processes are the outcome of a long development path. Many of the industry’s global leaders are well-established, for example Bechtel is over 100 years old and other firms like Hochtief, Skanska, and AECOM can trace their origin stories back over a similar period. Shimizu is over 200 years old. It’s a remarkable fact that construction today is a technological system that has been developing for more than 150 years, since the arrival onsite of steam, steel and concrete in the late nineteenth century.

How a new technology spreads through the economy and society is determined by many factors, however studies of historical cases such as tractors, electricity, TV and phones have given good examples of technology diffusion and its dynamics. A new technology takes time to diffuse because parallel changes in forms of organization, methods of production and patterns of consumption are required, and these are not decisions firms and households make quickly or easily. Studies on the introduction of new technologies found it typically takes 15 to 30 years for a new technology to reach 90 percent of its potential market, for example electrification in the US took 30 years from 1900 because of the fundamental changes industry and households needed to make to take advantage of electrical power.

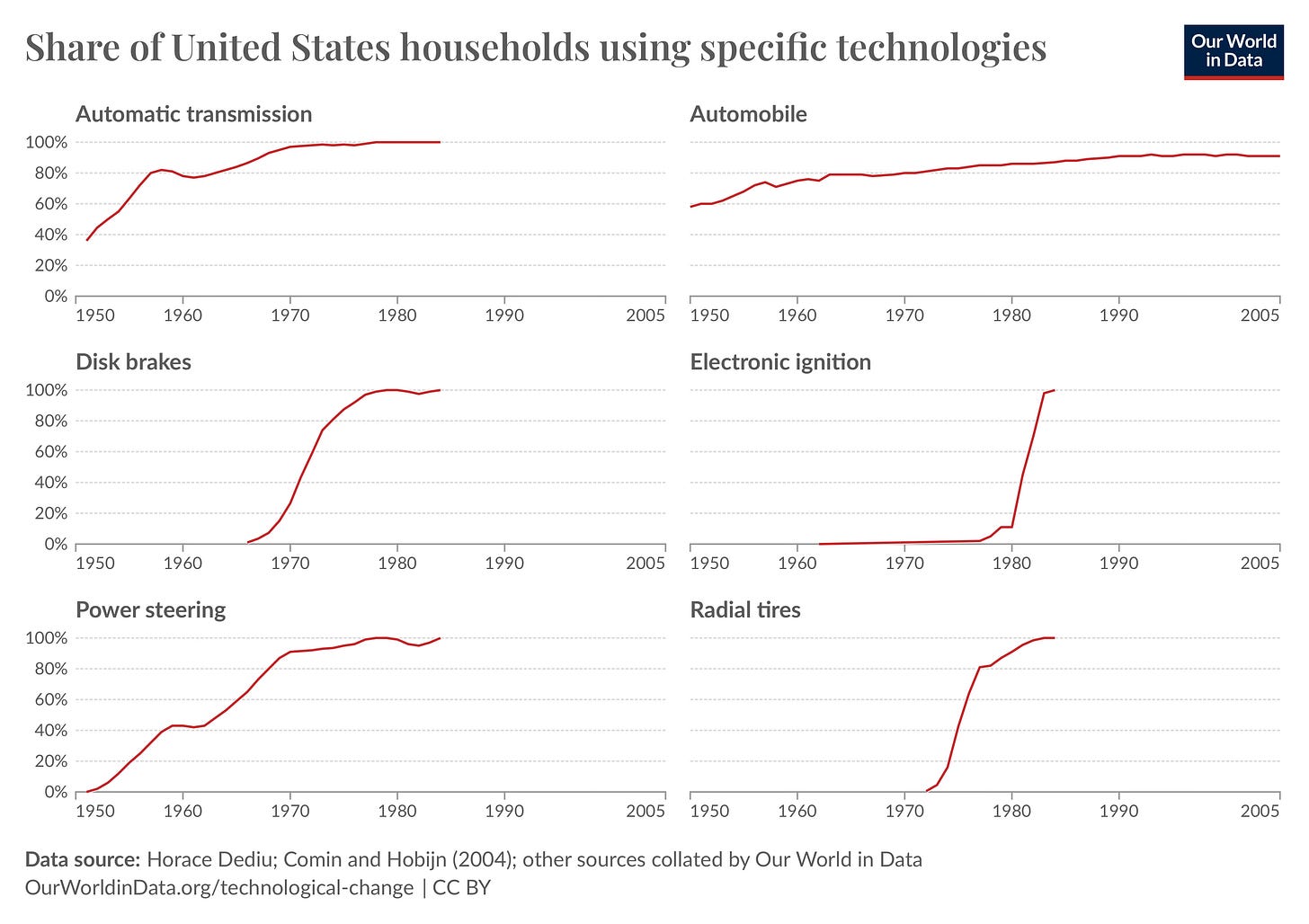

That it takes two or three decades for a new technology to become widely used is generally true, but the adoption path is different for each technology. For example, the speed of uptake of IT by US households was much faster for smart phones and social media than for computers and the internet, with the former reaching 80 percent in a decade while it took 20 years for the latter (Figure 1). Tablets took 5 years to get to 60 percent. For household appliances there is a similar story, with microwave oven and refrigerator use rising quickly over a decade to nearly 100 percent, while it took 60 years for washing machines and 40 years for air conditioning to reach 80 percent. Dishwashers took 40 years to get to 60 percent of households. All of these would be regarded as successful innovations, but their adoption rates varied greatly.

Figure 1. Adoption rates for household technologies 1920-2019

Another example is the number of tractors on farms, as the tractor displaced horses and mules in US agriculture between 1910 and 1960. Horses and mules declined from about 26 million in 1920 to about 3 million by 1960, while the number of tractors rose from zero to 4.5 million by 1960. One reason for the slow spread of tractors was the incremental innovation needed to increase their quality and reliability. A second was labour shortages and an increase in farm wages after 1940. The relative prices of labour and mechanisation have been found to be the most significant factor in technological innovation, diffusion and automation.

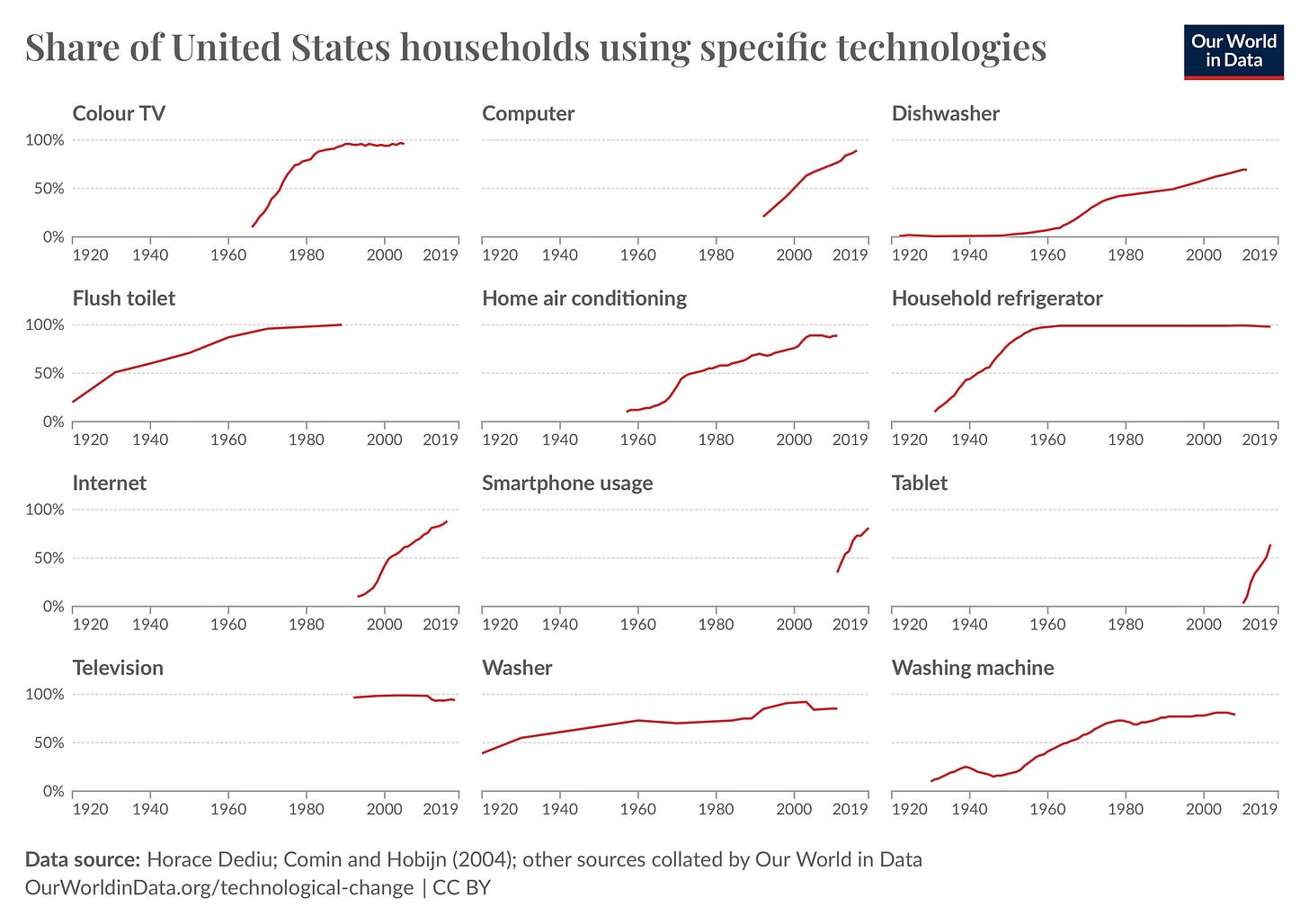

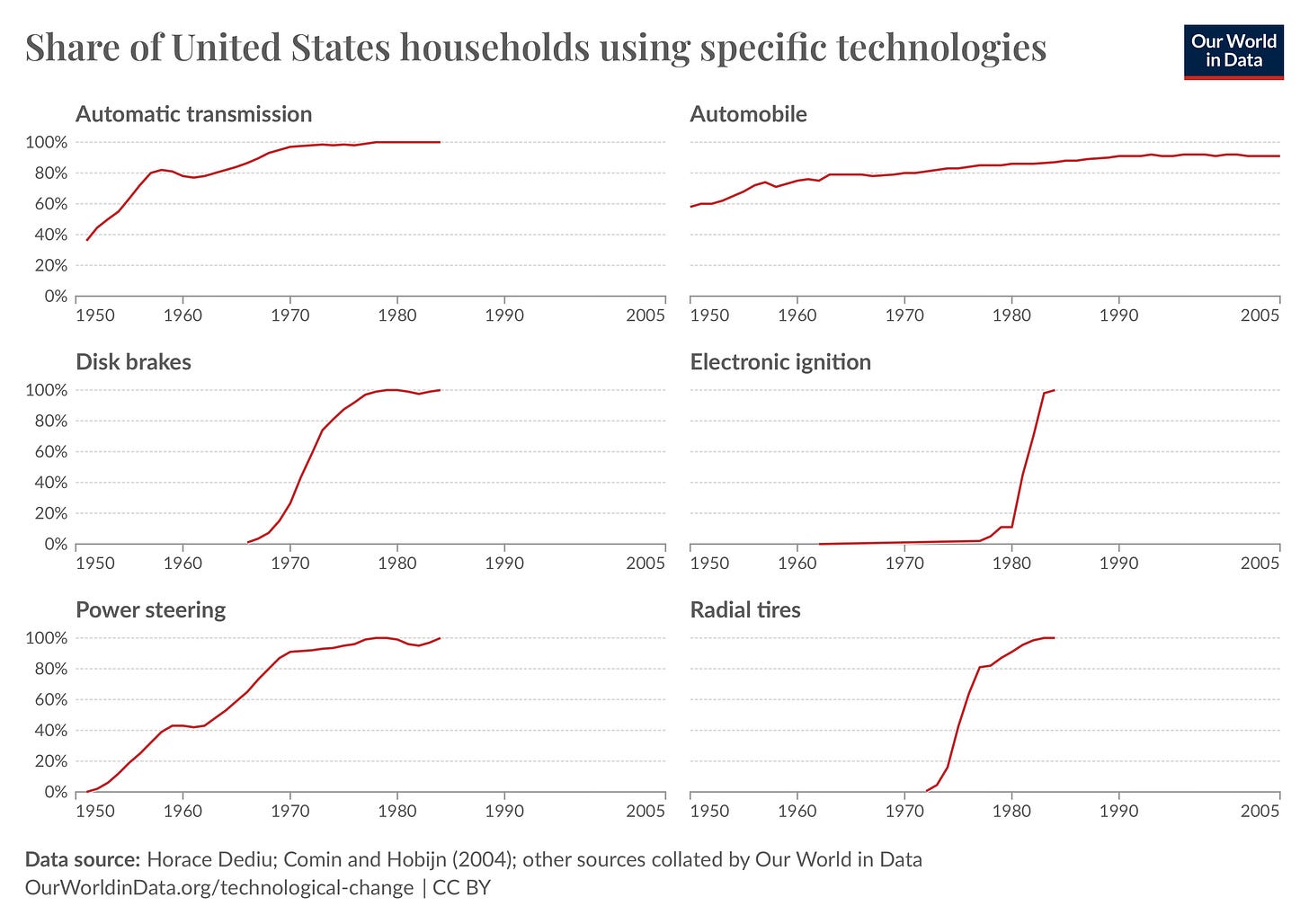

Oligopolistic industries with a few dominant firms like automobile manufacturing can scale innovations relatively quickly and successful innovations like disk brakes, electronic ignition and radial tyres can reach 100 percent usage in a decade or so, as Figure 2 shows. If one manufacturer improves their product with a new technology (the innovator) the others will follow (the imitators), otherwise they risk losing market share. This behaviour gives the S-shaped technology diffusion curve in these figures, rising quickly as imitators take up the technology and flattening out when maximum market share is reached, a dynamic also at work in consumer markets. In less concentrated industries with more manufacturers and dispersed, competitive markets, few technologies will be able to reach 100 percent of their potential market. Plastic water pipes have not replaced copper piping for example. In a few countries automated cabinetry and prefabricated houses have large market shares, but not in others.

Figure 2. US adoption rates for automobile technologies 1950-2005

Technology Diffusion in Construction

Technological diffusion in an industry like construction is affected by an interlocking set of economic, political, legal, and social barriers that make innovating difficult. As long as current technology meets the expectations of clients and users for prices and dominant products, there are significant market imperfections such as network economies, lumpiness, split incentives, requirements for collective action, and transaction costs, that inhibit diffusion and can block entry of more efficient, advanced technologies. There is also an institutional structure that imposes regulatory hurdles or other policy disadvantages, favours existing technology or discourages new entrants, with politically powerful vested interests who resist the introduction of threatening technologies supported by a financing system based around incumbents. Educational curricula, career paths, and professional standards use existing technology. For buildings and structures safety is a major issue.

How firms utilise technological capabilities differentiates them within construction’s diverse, location-based production system, not only because of the number of small and medium size firms, but because of the size and reach of the major firms. A global contractor might have over 50,000 employees, suppliers of basic materials and sophisticated components are large multinational or multilocational industrial firms, there are some large global consultants and project managers, many of these firms are publicly listed, and so on. These firms have the management and financial resources required to invest in twenty-first century technology, if and when they decide to do so. The issue here may be the ability of incumbent firms to capture knowledge externalities, adopt new technologies, and adapt to the impacts of emerging technologies and their requirements.

Innovation in construction is not easy. New products are typically based on years of research and development that turn an invention into a usable technology [1]. After the launch of a new product the technology will follow an adoption path, and successful technologies will gain market share over periods ranging from a few years to several decades as products based on them improve and become more widely used. Firms’ investment in equipment, software, training and design supports the innovation required to remain competitive, although very little of that investment is included in industry R&D statistics that only include expenditure by research labs and institutions.

Construction is a mature, project-based system of production with complex professional, organizational, contractual and working relationships, and is geographically distributed. Moreover, the context is one of wider networks containing many small and medium size firms with a range of organisational and institutional relationships, where external contracting is common. All these factors are seen as inhibiting, although not preventing, innovation and diffusion of new technology.

Hidden Innovation in Construction

A great deal of construction innovation is ‘hidden’, either inside the structure or in process innovations in onsite work, such as powered hand tools or new lifting and hoisting equipment. Higher standards for building materials’ fire, thermal or seismic performance are not visible, improvements in their air quality or energy use are not obvious to users, and products like ducting, composite wiring and plastic pipes are inside the structure. Hidden innovation is often an incremental upgrade of a current product or system. Process innovations that improve site efficiency do not benefit clients and customers directly, they will generally be captured by the contractor through higher profits (or lower losses) on a project rather than passed on to clients through lower price or better quality.

Piping and plumbing provide good examples of hidden innovation in construction of the built environment. Flushing toilets are one of the most successful inventions of all time and are themselves visible. However, the piping, drainage and sewerage systems that were required, and the pumps and equipment needed to make the system work, are largely out of sight. The use of PEX pipes in plumbing provides another example. PEX pipes are made of cross-linked polyethylene and, as an alternative to PVC or copper, are used for water distribution, heating and cooling. Invented in Germany in 1968, PEX became available in Europe in the early 1970s and in North America in the mid-1980s, where it took 30 years to take half the piping market in residential construction but made little inroads in use for commercial buildings.

Some household technologies required new structural elements in buildings, and to an extent can also be regarded as construction innovations. Refrigerators require electricity, and the first building codes in the 1890s were for electrical systems and components. Flushing toilets, central heating and ducted air conditioning were new functions that became incorporated into the product, and by the mid-twentieth century the basic parameters for building design and materials were in place based on codes that are regularly revised to set higher performance standards. The functionality of housing has not fundamentally changed since, and continuing production, product and process innovations have been hidden from consumers and users.

The technology adoption rate in construction might be more like the one seen for household appliances than automobile manufacturing, where the basic function of the product is transport and the industry is concentrated in half a dozen global manufacturers. Construction is a dispersed market with many customers requiring different functions spread out over different locations. Contractors are typically local firms, and their suppliers range from small workshops to giant multinational corporations, allowing opportunities for substitution between products that are inside the structure and hidden from users and consumers. Local markets also have characteristic preferences in design and materials, particularly for houses. With design decisions and specifications made from project to project and familiar products usually favoured, gaining market share in construction for a new product will be a slow process that requires commitment and resources to be successful. This characteristic also means many innovations have never achieved scale or significant market share.

An example is the market for external cladding for buildings. To the traditional materials of wood and brick have been added glass, concrete, metal, ceramic, vinyl, composite and fibre cement alternatives, all of which have continuing significant shares of the total market. There are over a dozen major manufacturers who all have large market shares in some, but not all, regional markets (like Europe, East Asia, Central, South and North America). The most recent innovation is HardiePlank, a fibre cement panel invented in Australia in 1986 that took 20 years in the US to reach 20 percent of the housebuilding cladding market.

Conclusion

In the second half of the 1800s steam power and the new materials of glass, steel and reinforced concrete arrived, bringing with them new business models and new entrants. Nearly two hundred years later construction is a mature industry, based around standards and professional roles, with a high degree of technological lock in due to the age of the system. The ‘embeddedness’ of the construction technological system is found inside professional institutes and organizations, trade and industry associations, government regulations and licensing, standards and codes, insurance and finance providers, and the regulators.

There are two distinctive characteristics of construction innovation and technology adoption. The first is the fragmented, dispersed market for construction, where new products have to gain market share project by project against existing products. The second is the extent of ‘hidden’ innovation that improves the performance of buildings. Hidden innovation improves performance of a product but is not visible to the user or customer. Examples of hidden new technologies in automobiles are disk brakes and electronic ignition, neither of which would register with most car drivers.

Construction today is a dense, highly regulated network of industries, with powerful incumbents in many parts of the supply chain, using standardised materials and components to deliver buildings and structures using well understood processes. Incremental innovation is widespread, but not obvious when dispersed over many projects in many places, or hidden inside the building and not seen by users.

The modern system of constructing the built environment may not be elegant, but it is a flexible, sophisticated and resilient system that coordinates many firms in a widely distributed value chain. Because this is a very efficient system, a new technology has to perform extremely well to have any significant effect.

[1] A previous post was on Incremental innovation in construction: The example of concrete

Thanks for putting this together. Path dependence is an important issue when it comes to breaking through change resistance, as is the fragmented nature of the industry as you point out.